Counterproductive flush water in an evaporator pump leads to big savings

During an energy audit at a Canadian pulp and paper plant, AESSEAL® identified 15 packed evaporator area pumps that needed upgrading to mechanical seals. This was due to the packing flush water diluting the black liquor which was already trying to remove the excess water to enable its use as fuel for their recovery boiler.

Click to Download

Preventing toxic leakage and improving reliability

A major paper mill in Canada were having on going issues with the sealing of their Chlorine Dioxide Generator recirculation pump. Having tried mechanical seals from other manufacturers without success, the customer had resorted to using gland packing and a ‘Pack-Ryt’ bushing.

Click to Download

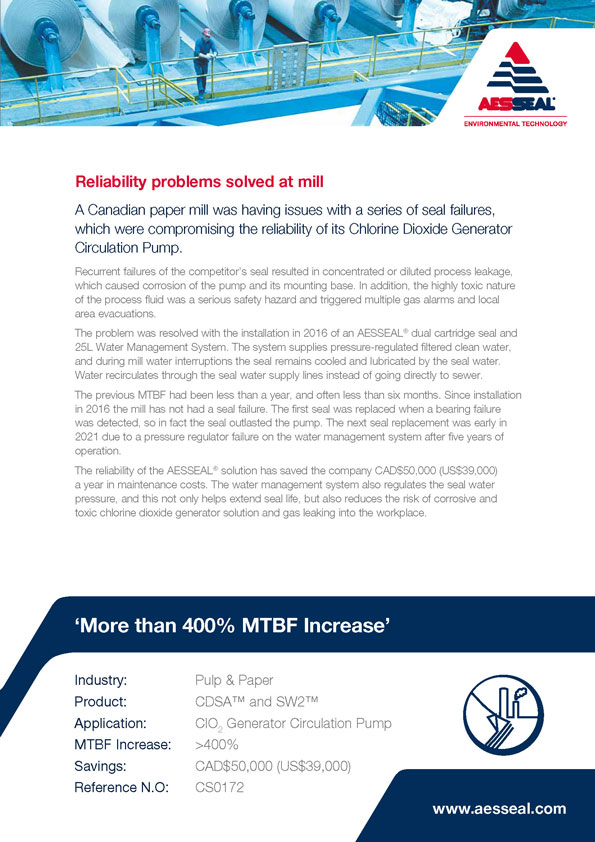

Reliability problems solved at mill

A Canadian paper mill was having issues with a series of seal failures, which were compromising the reliability of its Chlorine Dioxide Generator Circulation Pump.

Click to Download

Eliminating over 61 million gallons of water from 26 evaporator pumps

In this case study evaporator steam use reduced by 103,000klbs a year by eliminating over 61 million gallons of water from 26 evaporator pumps.

Click to Download

Reliability upgrade reduces water consumption

Kraft pulp mills with recovery boilers have multiple effect evaporators and concentrators to reheat and remove water from the returning Weak Black Liquor from the cooking process.

Click to Download

Fantastic seal life for notoriously difficult application

A pulp & paper company in the Canada were dissatisfied with the reliability of the mechanical seal used in its Chlorine Dioxide generator pump.

Click to Download

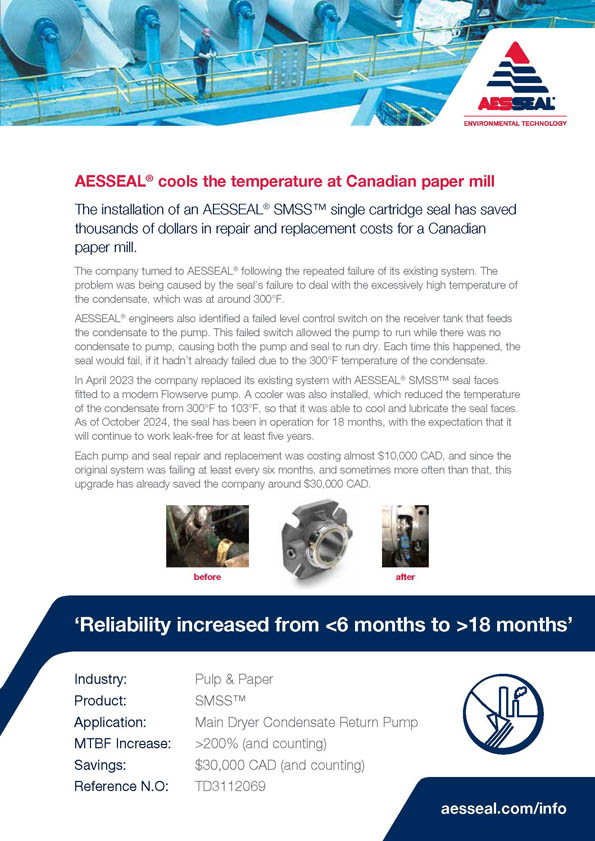

AESSEAL cools the temperature at Canadian paper mill

The installation of an AESSEAL® SMSS™ single cartridge seal has saved thousands of dollars in repair and replacement costs for a Canadian paper mill.

Click to Download